- +0086 731-86398845

- sales@mascoonsewing.com

- turkey@mascoonsewing.com

- Mon to Fri 8:00 am to 18:00 pm

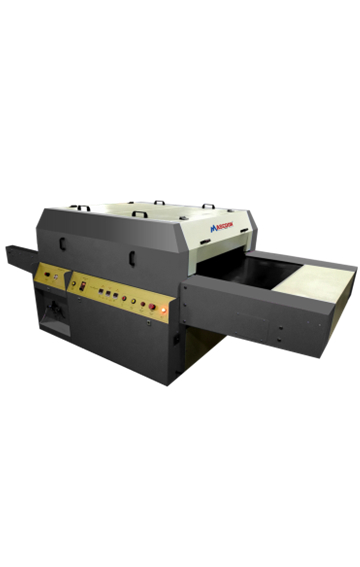

Crawler type continuous heat pressing fusing machine MS-600L/900L

Mascoon crawler type continuous heat pressing fusing machine MS-600L/900L are equipped with the latest design of pneumatic pressure shaft system, it could evenly distribute the colloidal particles between the cloth and interlining to further dissolve the colloidal particles to achieve better results.

Working Power:

22KW

Working Voltage:

3P-380V

Max Temperature:

195℃

Max Pressure:

0.5Mpa

-

Professional and Efficient Crawler type continuous heat pressing fusing machine

Mascoon crawler type continuous heat pressing fusing machine is equipped with the latest design of pneumatic pressure shaft system. It will not increase the pressure on the cloth and there's no any influence on the touching feeling of the fabric at all. With cooling device for discharging, it can make the fusible lining cool down quickly, thus improve the working efficiency.

-

Machine devices are more powerful and durable

The pressure axis is independently controlled, which can achieve more subtle adjustment for the full adhesion of different cloth and interlining cloth. It's used the cylinder tightening device for the adjusting device of pneumatic and belt so that the conveyor belt could be more stable and durable. The inner tightening method and dual cleaning device of the belt greatly reduce the damage of the belt, making the using life of the belt improved.

-

More effectively make the material to achieve high quality requirements

Two models, independent temperature control device which can heat the cloth gently so that the material overall color unity, to achieve high quality requirements.

-

Functions and Features

1. Equipped with the latest design of pneumatic pressure shaft system, it could evenly distribute the colloidal particles between the cloth and interlining to further dissolve the colloidal particles to achieve better results.

2. It's adopted the rotary plucking device for discharging to force the material stripped.

3. With cooling device for discharging ,it can make the fusible lining cool down quickly.

4. The inner tightening method is adopted to avoid the residual cloth and interlining cloth being attached to the shaft and greatly reduce the damage of the belt.

5. It's adopted the dual cleaning device for the belt which could be cleaned automatically outside and inside,making the using life of belt improved.

6. With max diameter 145mm and silica gel axis design,it could be suitable for all kinds of materials.

7. For model MS-600L, it's divided the 6 groups of the heating area into 2 groups of independent devices which are designed to heat the cloth gently and the interlining cloth more delicately. It reaches 1.3m long for the heating area, making the belt stick to the cloth more effectively and the overall color of the material be unified to achieve high quality requirements.

8. For model MS-900L, it's divided the 9 groups of the heating area into 3 groups of independent devices which are designed to heat the cloth gently and the interlining cloth more delicately. It reaches 1.6m long for the heating area, making the belt stick to the cloth more effectively and the overall color of the material be unified to achieve high quality requirements.

Techspecs:

Model

MS-600L

MACHINE SIZE

315*125*135cm

POWER

22KW

MAX TEMP

195℃

VOLTAGE

3P-380V

MAX PRESSURE

0.5Mpa

HEAT SIZE

Width 600mm

Model

MS-900L

MACHINE SIZE

340*155*135cm

POWER

22KW

MAX TEMP

195℃

VOLTAGE

3P-380V

MAX PRESSURE

0.5Mpa

HEAT SIZE

Width 900mm

Watch Video:

Get a Quotation

Get latest price for seamless machines from Mascoon Sewing

Describe your needs in detail.

Get a Quotation from Mascoon Sewing

Get a quotation and we will reply within 24 hours.